Kaizen is no new concept, it is quite an old concept well renowned in the industry, in relation to quality management.

Most sectors nowadays must adapt quickly to a changing environment, in a nearly organic manner. There is that resistance to change nearly inherent to human beings. Once we are used to something, and we are agile in a specific process, it takes a while for us to amold to a change that means learning a new technology, forgetting or unlearning the previous process.

Considering that a new adjustment or process would be beneficial, could it be that adding a new process would be what causes the initial friction?

How many of the changes you experienced in the last year meant learning to use a new tool or software?

There are possibly workers that can manage their jobs with 2 or 3 tools, buy I would dare to say that most of us use at least 5 or 6. Is that too much? Without too many details, I can count: Task and team manager + internal communication tool + online cloud storage + CRM + ERP + Invoicing system ; Shared document editor + Wiki + Password manager + Video conferencing system + Email + Time tracker + Process automation and workflow management…

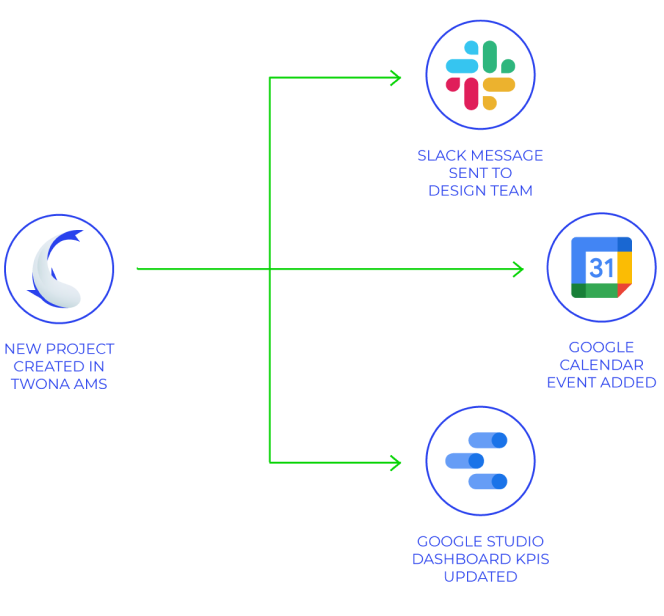

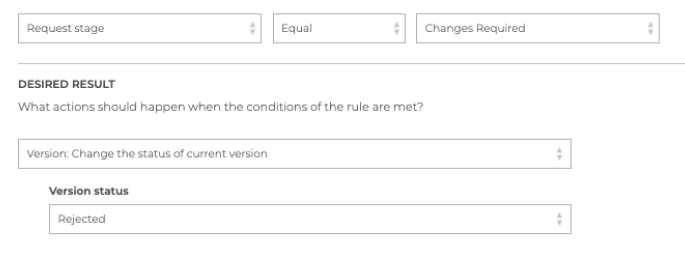

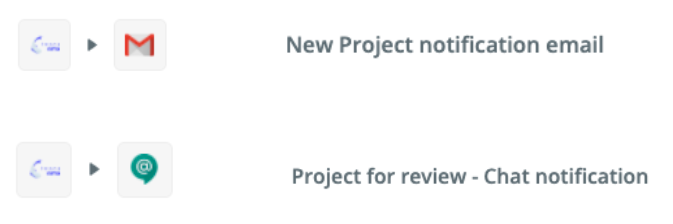

So, just working with half of these tools is quite a lot to use on a daily basis, each team would have their own tools to manage and control their processes in the best way possible. Does it mean that we have enough and we cannot absorb any more tool-related changes? I do not have an answer to that but I do not think that is the best approach to the matter. It is, however, the time to reflect on how the process can be simplified, which is why I am taking on the automation of processes or integrations.

In that search for continuous improvement through change, it could be that we have become obsessed with wanting to use the best tool for everything – the most complete CRM, with a task manager and teams easy and usable; tools to communicate; intuitive invoicing system; and organized resources planning to link operations in different areas, ERP.

Do not get me wrong. Of course, we all want the best for our teams, and we want to provide the best in market tool for each process. But, sometimes, when we study processes from a top perspective, looking at the big picture, maybe the answer is in learning the connection between different tasks to create a sequence and automate as much as possible.

Is tool integration the new Kaizen of our time?

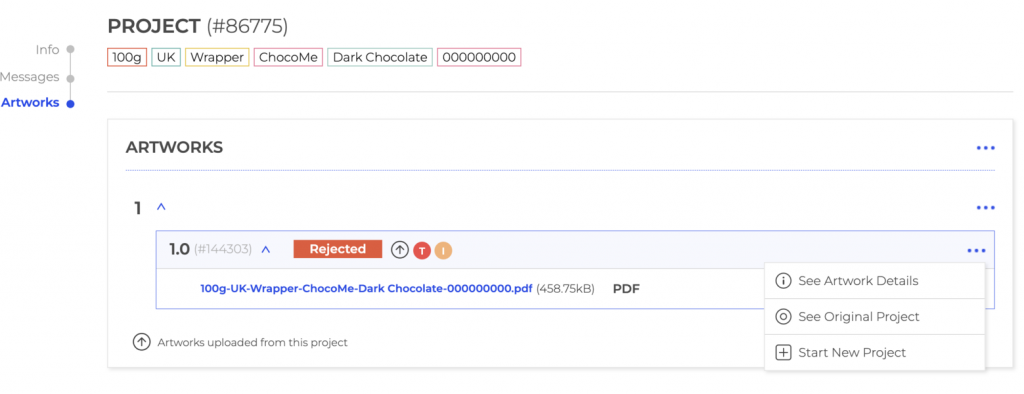

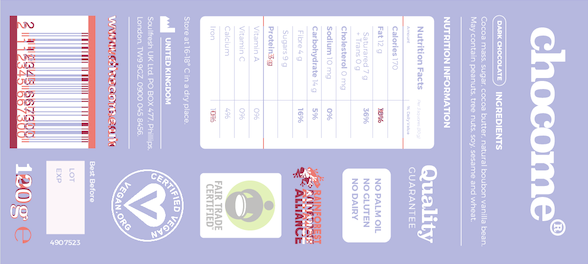

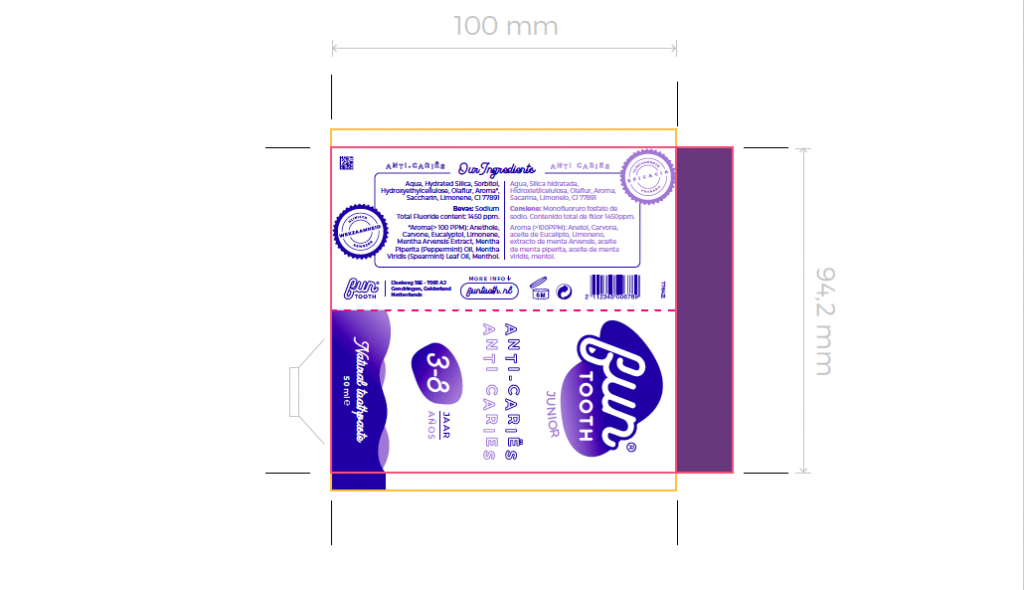

Artwork Manager