Anyone who has worked in pharmaceutical packaging knows the drill: you think you are done with a design, it’s ready to go, and then… a new change request comes in. And not just any change; a change that involves multiple departments, extensive back-and-forth communication, and, inevitably, hours of work.

This creates a lot of frustration in the design teams. However, it’s not about the design itself. It’s the chaos and frustration that surrounds it. Here is what typically happens when your design team faces an artwork update:

Endless Feedback Loops

Artwork changes are often passed around between multiple departments: Quality, Regulatory, Register, and Commercial/Marketing. Each department reviews, revises, and then sends it back, separately, to the design team with their feedback.

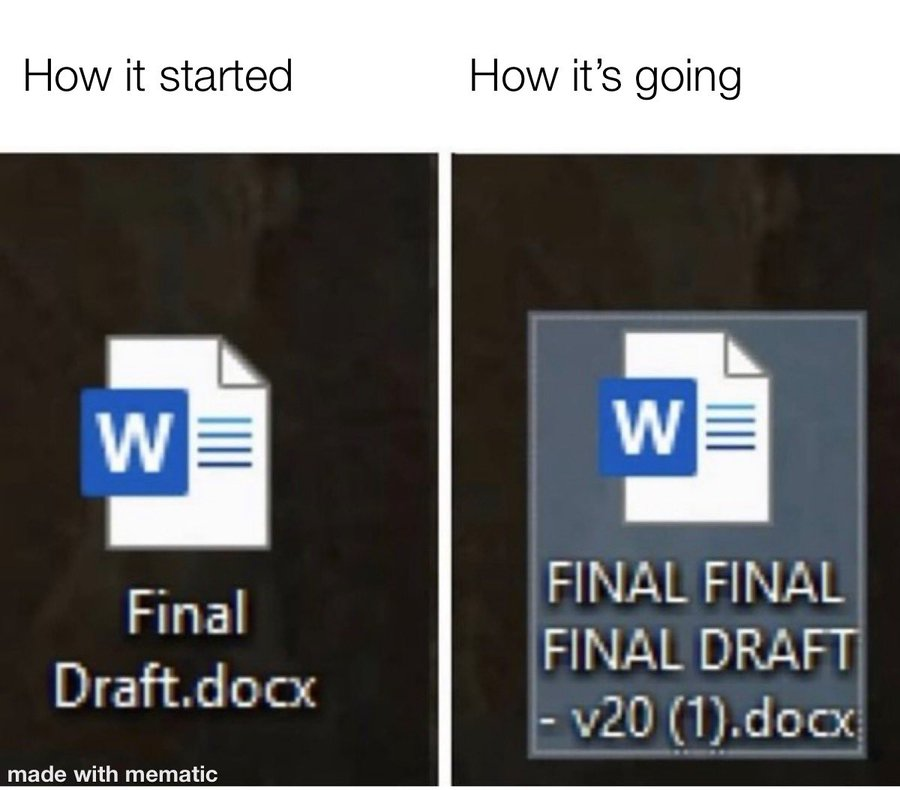

Confusing Version Control

How many times have you heard the phrase, “Which version is this?” With so many hands in the process

and multiple versions of the same artwork flying around, it’s easy to lose track of what’s been approved, what’s in progress, and what’s been rejected. This confusion leads to miscommunication, delays, and errors that ultimately cost time and money.

Last-Minute Legal/Regulatory Changes

Every time there’s a minor legal update or regulatory change (and this happens a lot in pharma), it requires last-minute revisions to packaging. These changes are often urgent, and because they’re so critical to compliance, there’s little room for error. Your designers are expected to respond quickly and get it right the first time, which can be a huge source of stress.

The Fear of Missing Small Details

In pharma packaging, every detail matters. The tiniest mistake in the artwork, whether it’s a text error or a missed symbol, can lead to serious consequences, such as product recalls, regulatory fines, or worse.

Design teams know this, and that’s why the pressure of making those changes without missing anything is enough to make them dread the entire process.

So, what is the solution?

The good news is that there’s a way to make artwork management easier, faster, and less stressful for everyone involved.

The key is to centralize and streamline the process using an Artwork Management platform designed specifically for the pharma industry. Here’s how it works:

Centralized Feedback and Approvals

Instead of bouncing emails back and forth and risking confusion, an artwork management platform allows you to centralize all feedback and approval processes in one place. This ensures that all stakeholders – regulatory teams, quality, medical affairs, or marketing – can review and approve changes in real-time, without missing anything.

Full Version Control and Traceability

With a centralized platform, version control becomes simple. Every change is tracked, and all stakeholders can see the latest updates clearly, and in one single place. You’ll no longer need to ask, “Which version is this?” or risk working with outdated designs.

This feature also gives you a clear audit trail, ensuring that you can quickly trace any movements made to the artwork, which is especially critical in a heavily regulated industry like pharma.

Speeding Up Time-to-Market

When artwork approvals happen faster, your products get to market quicker. An effective artwork management solution can cut down approval times by up to 60%*, which means your design team can focus on important work without being bogged down by endless approval processes.

Ensuring Regulatory Compliance

Pharma packaging needs to comply with a lot of regulatory standards. With the right system in place, your design team doesn’t have to worry about missing critical updates. Everything is built to ensure compliance, making the process smoother and reducing the chances of mistakes that could lead to recalls or legal issues.

How can an artwork management system benefit your design team?

When your design team is freed from the constant back-and-forth, version confusion, and last-minute changes, they can focus on what they do best : creating designs that stand out on the shelf.

By simplifying the artwork management process, you’re not only reducing the stress on your design team but also improving overall efficiency and product quality.

* https://www.linkedin.com/pulse/how-does-artwork-management-software-affect-bottom-line-mansi-s-/

Ready for the next step?

If you want to see how pharma companies are improving their artwork management processes, and making life easier for their design teams, let’s talk. https://www.twonas.com/contact/