Having a single source of truth is a key aspect of effective design management, particularly when it comes to packaging materials and more so in highly regulated environments where a recall is akin to….well….the devil. When multiple stakeholders play a key role, it’s essential to have a clear and centralized system for managing the design process to ensure consistency, accuracy, and efficiency.

Centralised Source of Truth

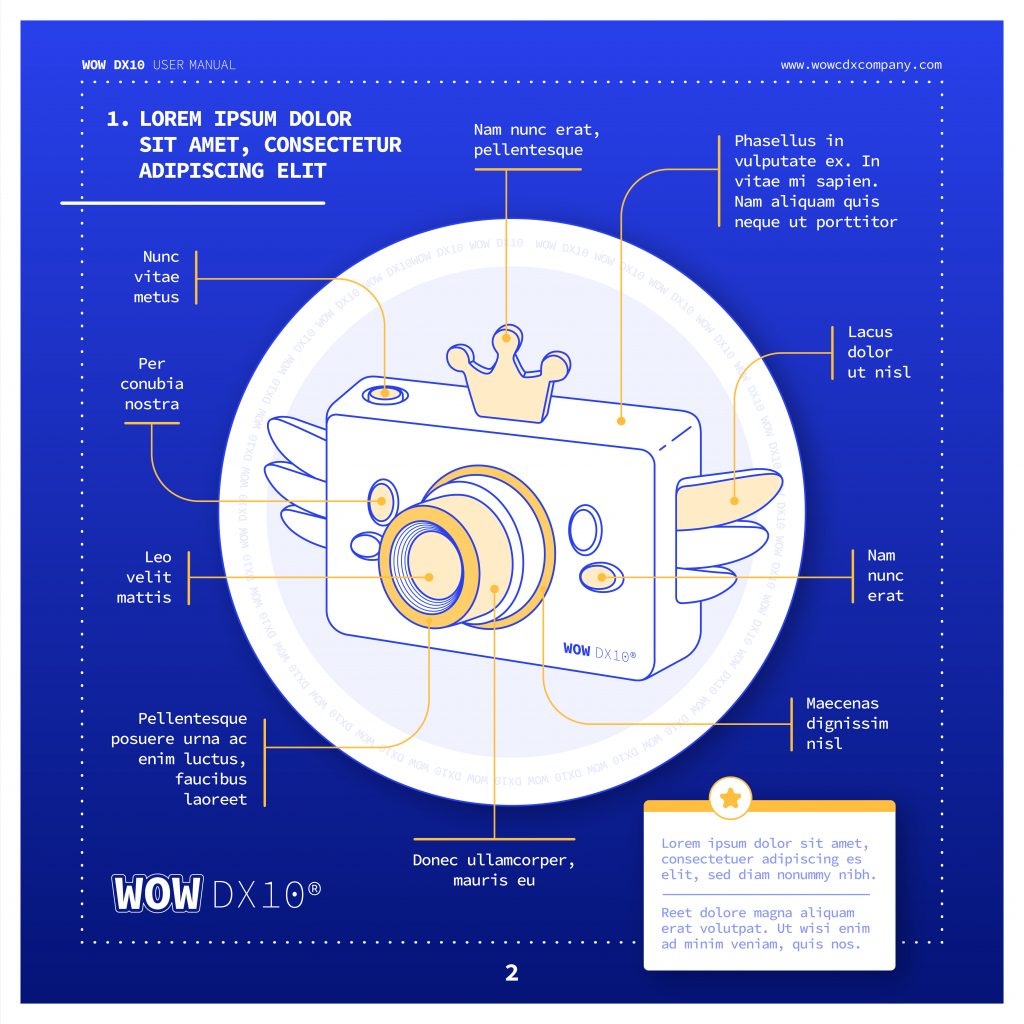

A centralized source of truth refers to a single, authoritative repository of information or data that serves as the authoritative reference for all stakeholders involved in a project. In the context of managing design files, a centralized source of truth refers to a centralized system or platform where all design files, specifications, and other relevant information are stored, managed, and updated. This system serves as the authoritative reference for all stakeholders involved in the design process, including designers, regulatory affairs specialists, quality managers, marketers, printers, production specialists and other decision-makers.

The purpose of having a centralized source of truth is to ensure that everyone involved in the project is working with the same information and that everyone has access to the latest version of the design files. This helps eliminate confusion and miscommunication and ensures that everyone is working towards the same goal.

A centralized source of truth also makes it easier to track changes and maintain version control. All updates and changes to the design files are made in one place, making it easier to keep track of who made changes and when. This helps reduce the risk of errors and inconsistencies and ensures that everyone is working with the latest version of the design files.

Three key aspects

Here are three of the most important aspects of having a single source of truth in this context.

- Collaboration and Coordination: Having a single source of truth makes it easier for all stakeholders to collaborate and coordinate on the design process. Instead of having multiple versions floating around in different folders or email attachments, everyone has access to the same information, making it easier to track changes, communicate with each other, and ensure everyone is working in sync.

- Version Control: In a decentralized system, it can be challenging to keep track of which version of the design is the most recent and accurate (have you ever seen version 1, version 1_new, version 1_new_new? kind of thing). This can result in errors and inconsistencies in the final product. Having a single source of truth allows for accurate and safe version control and ensures that everyone is working with the latest information.

- Traceability and Auditability: Having a centralized and well-organized system for managing the design process helps ensure that all decisions are properly documented and can be traced back to the original source. This is important for ensuring accountability and maintaining a clear record of the design process. In the event of a problem, it’s much easier to determine who made a decision and why, which can help minimize the risk of costly mistakes and protect the company from liability. If you work under highly regulated agencies (pharma, food, etc) this is not even a nice to have, but an absolute must. If you are managing files using sharepoint or local folders…..God had mercy on your soul if you ever have to undergo an audit.

Risky Business

The biggest risk of not having a single source of truth and relying on shared folders or decentralized systems is the potential for a failed design to make it to the market. This can result in negative consequences for the company, such as lost sales, decreased brand reputation, and increased costs for correcting the problem. Bonus risks and costs if you are dealing with a pharmaceutical product that can kill a patient. Having a centralized and well-organized system in place helps minimize this risk by ensuring that everyone is working with the same information and that the design process is properly documented and auditable.

If you are still working with Excel files and local folders….well…..I mean…..its 2023…..you don’t have to do that anymore.