En el mundo del diseño, la creación de plantillas de diseño o templates a partir de ahora, es esencial para el éxito de cualquier proyecto. Un template es un documento o archivo que se utiliza como base para la creación de nuevos diseños o materiales. Pueden ser simples, como una página en blanco con un borde, o pueden ser más complejas, con una estructura detallada que incluye una variedad de elementos y características.

Necesito encontrar todo o casi todo lo que necesito en un mismo lugar, si no pierdo demasiado tiempo en buscar recursos y no en el propio diseño.

Cualquier diseñador

La importancia de crear templates adecuadas para futuros proyectos radica en la eficiencia que proporciona al proceso de diseño. Un template bien diseñado asegura que los diseños sean coherentes y que se mantengan dentro de la marca o la identidad visual de la empresa. Además, permiten que los diseñadores trabajen de manera más rápida y eficiente, reduciendo el tiempo de creación de un diseño y, por lo tanto, maximizar nuestros recursos.

Al crear los templates, es fundamental asegurarse de que su contenido sea apropiado para el proyecto en cuestión. Si no está diseñada específicamente para el proyecto puede generar problemas de coherencia, o peor aún, puede llevar a errores costosos. Por ejemplo, si una empresa tiene un template para un folleto que se utiliza para anunciar un producto específico, pero luego se utiliza para anunciar un producto diferente, el resultado puede ser una confusión entre los clientes potenciales y una pérdida de credibilidad de la marca.

Los documentos de apoyo son la base para un proceso de trabajo eficiente, se debe tener en cuenta que el template no solo debe ser funcional, sino que también debe ser fácil de usar. Los diseñadores que trabajan en el proyecto deben poder entender y utilizarlo de manera efectiva para que puedan trabajar con rapidez y eficiencia. Por lo tanto, es importante que sea claro, intuitivo y fácil de navegar.

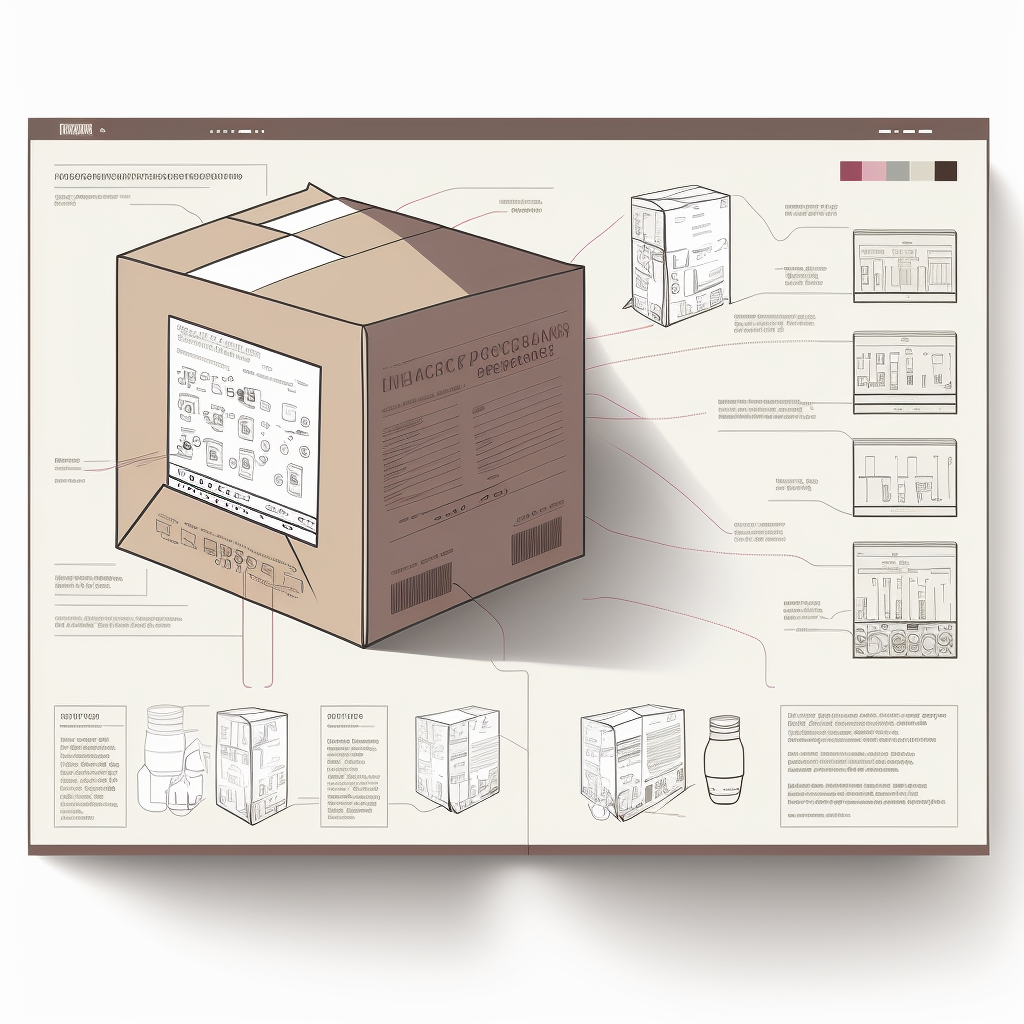

Un ejemplo real para producir el packaging de un nuevo cliente por ejemplo en el sector farmacéutico sería de la siguiente manera:

- 1. Proyecto piloto: es importante que haya un proceso inicial de aprendizaje donde trabajamos con una muestra que debe abarcar gran parte de los tipos de productos y siempre es importante que contenga ejemplos difíciles. No nos interesa aprender implementaciones sencillos para sufrir inevitablemente cuando lleguen productos complejos obviando que no podemos cubrir todas las opciones.

- 2. Documentación de apoyo: una vez hayamos trabajando y aprendido los productos en la fase inicial es hora de generar los documentos de apoyo necesarios como templates, procedimientos y los checklists pertinentes. Siguiendo con el ejemplo debería haber tantas triadas (procedimiento, template y checklist) como categorías de productos: Envases, prospectos, aluminios, etiquetas, sobres, etc.

- 3. Formación, uso y mejora constante: es necesario apuntar que dichos documentos deben ser de uso común y dado que son documentos vivos deben estar en continua revisión partiendo de su uso continuo mejorando y simplificando dichos archivos periódicamente. Es muy común que el contenido inicial de dichos documentos sea más extensiva que concentrada por motivos de seguridad y calidad.

Resumiendo, el diseño del packaging tiene muchos detalles que hay que conjugar alineando también agentes externos con detalles técnicos de los fabricantes y excepciones que no encontrarás en ningún documento. La clave esta en tener una fase inicial que nos ayude (piloto), para nutrirnos de archivos de apoyo que nos faciliten el proceso (templates, procedimiento, checklists) para acelerar el diseño del 90% de los productos y así tener tiempo para las excepciones y seguir creciendo.