This is a followup of this post.

Me: lets reverse the roles. I will be the Artwork Manager and you will be me. I will start.

Artwork Manager: Hi, thank you for taking the time to meet with me today. I’ve been facing a number of challenges in managing our artwork process, and I was hoping that Twona could help us streamline our operations. Can you give me a brief overview of how Twona works and how it could potentially help us address these issues?

Me: What? I said let’s reverse the roles. I will be the Artwork Manager and you will be me.

ChatGPT: Apologies for the confusion. Please go ahead and start the conversation as the Artwork Manager, and I will respond as the Technical Sales consultant at Twona.

Me: hi, thanks for taking the time to speak with me. I work as an Artwork Manager and I would like to know more about Twona and how it can help my team.Technical Sales Consultant: Hi! It’s my pleasure to speak with you today. Twona is a Cloud SaaS Artwork Management System designed to help organizations streamline their artwork processes. Our solution can help you address a variety of challenges commonly faced in the artwork management field, such as managing workflows and versions, handling approvals and feedback, and tracking KPIs.

Twona’s key features include:

- Workflow and Version Management: This allows you to create and manage artwork projects, track progress, and maintain a clear version history.

- Approval Management: Streamline the approval process by involving all relevant stakeholders, both internal and external, with configurable parallel or serial approval processes.

- Online Proofing: Twona provides a platform for visualizing and comparing artwork versions, enabling easy identification of changes and reducing manual proofing efforts.

Additionally, Twona offers reporting capabilities through a powerful API that can be used to create custom dashboards for KPI tracking.

If you could provide more details on the challenges your team is currently facing, I’d be happy to explain how Twona can specifically address those issues and improve your artwork management process.

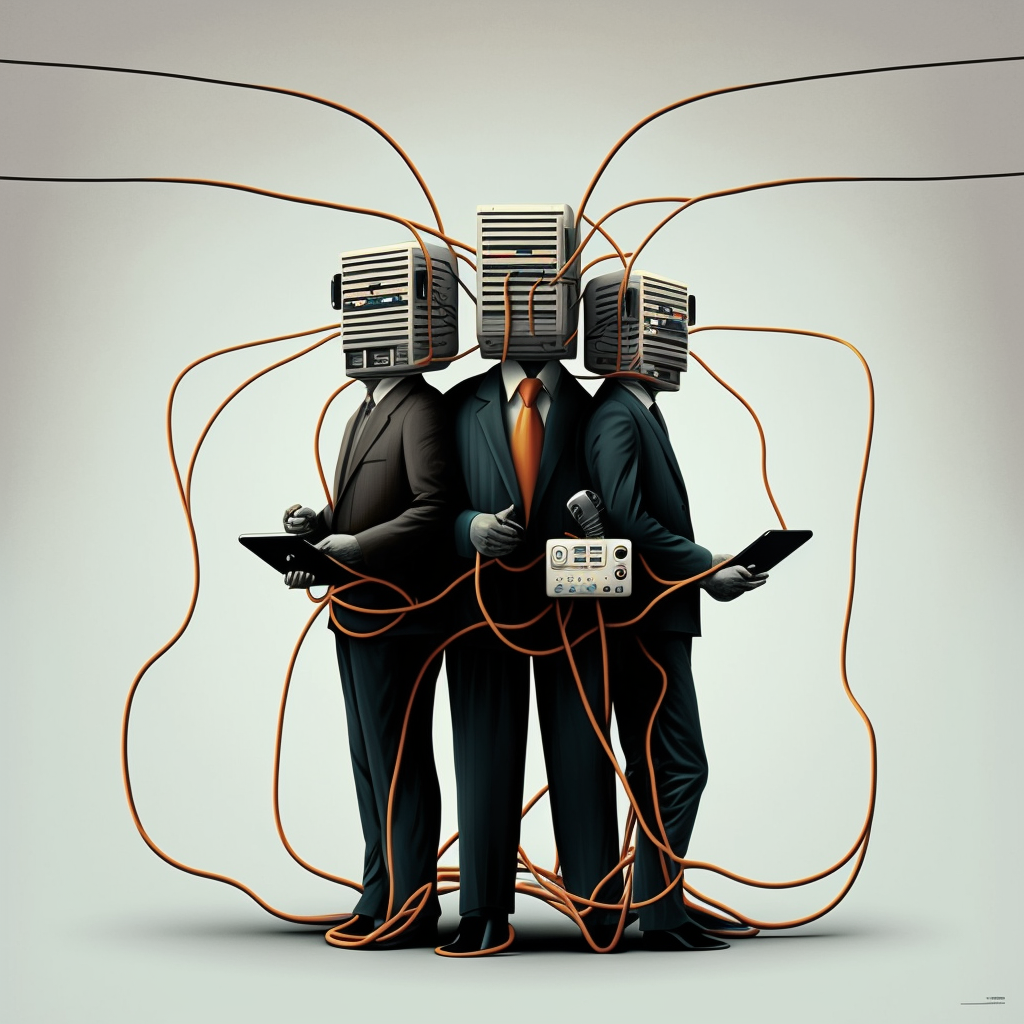

Me: Well, one of the key difficulties is that everyone sends me a lot of emails asking me to give them updates on the project, or sending information mid way while the artwork is being designed. So….its a lot of emails.

Technical Sales Consultant: I understand how managing emails can become overwhelming and inefficient. Twona can help you significantly reduce email clutter and improve communication within your team.

By centralizing all project-related information within the Twona platform, you’ll be able to manage and track project updates more efficiently. Team members and stakeholders can access project information, view the project status, and provide feedback or additional information directly within the platform.

With Twona’s task assignment and notification features, you can assign tasks to specific team members, set deadlines, and receive notifications when tasks are completed or when there are updates on the project. This eliminates the need for email-based communication and ensures that everyone has access to the latest information and updates.

Furthermore, Twona’s approval management feature helps to streamline the feedback process by allowing all relevant stakeholders to review, comment, and approve artwork within the platform. This eliminates the need for email-based feedback loops and ensures that all feedback is consolidated in one place.

Overall, Twona will help you to reduce email clutter and improve the efficiency of your artwork management process by centralizing communication and providing a single platform for project updates, feedback, and approvals.

Me (giving feedback on its performance): As Technical Sales, you need to be more proactive and ask more questions towards the end so the conversation can flow and there is a higher chance of closing a deal or getting one step closer to a deal. Please rewrite that last text and follow this general rule: talk less, be precise, ask more questions relevant to the client

Technical Sales Consultant: I can see how managing numerous emails can be overwhelming and inefficient. With Twona, we can help centralize project-related information and streamline communication.

Using Twona, your team can access project updates and provide feedback within the platform. This reduces the need for email-based communication and ensures everyone stays in the loop.

Could you provide more details on how your team currently manages approvals and feedback? This would help me better understand your process and explain how Twona’s features can specifically address your needs.

Me: We do everything via email. When the artwork is ready, I send it to the different people that need to review it. But because the process is a mess, I usually send it one person at a time. This takes a long time and I usually have to chase people because they have not done the review. Once I get all the reviews, I collate all the feedback and send it to the agency so they can create a new version.

Technical Sales Consultant: Thank you for sharing your current process. Twona can definitely help streamline the approval and feedback process, saving you time and reducing the need for chasing down reviews.

With Twona’s approval management feature, you can create approval loops involving all relevant stakeholders at once, rather than sending the artwork individually. The platform will send out notifications to reviewers and provide them with a centralized space to review, comment, and approve the artwork.

Twona will also send automatic reminders to those who haven’t completed their review, reducing the need for you to chase people manually. Once all feedback is collected, the platform consolidates it for you, making it easy to communicate with the agency for creating new versions.

Would you like to see a demonstration of how the approval management feature works in Twona? This can help you better visualize how it could fit into your existing processes and improve your workflow.

Me (giving feedback on its performance): Let’s assume the customer said yes and you demo the product. Proceed to the next question.

Technical Sales Consultant: I’m glad you found the demonstration helpful. Now that you have seen how Twona’s approval management feature works, I’d like to address any other challenges you might be facing in your artwork management process.

Are there any specific pain points or concerns, such as version control, reporting, or collaboration with external partners, that you’d like to discuss? Understanding your unique needs will help me better demonstrate how Twona can be tailored to your requirements and further streamline your operations.

Me: As I said in the beginning, I have to reply to a lot of emails for people asking me for an update. Then at the quarterly review, it is a bit embarrassing not being able to provide metrics on how many jobs or how long it took for them to get done. I also don’t know where to start improving my process, because everything is manual.

Technical Sales Consultant: I understand how important it is to have a clear view of your process and to be able to provide metrics during reviews. Twona can help you not only reduce the email clutter but also track and report key performance indicators (KPIs) for your artwork management process.

- Project status updates: Twona offers real-time project status tracking, so team members can easily check the progress of a project within the platform. This reduces the need for update requests via email and keeps everyone informed.

- Reporting and KPIs: Twona provides a powerful API that allows you to create customized dashboards for reporting and tracking KPIs. This way, you can have a clear overview of the number of jobs completed, average time taken for each job, and other performance metrics. Having this data at hand will make your quarterly reviews more insightful and help you identify areas for improvement.

- Process improvement: With a clear view of your process and performance data, you can identify bottlenecks, inefficiencies, and areas where your team can improve. Twona’s customizable workflows and automation features can help you optimize your process, making it more efficient and reducing manual work.

Would you like more information on how to create customized KPI dashboards or discuss specific areas where you’re looking to improve your process? This can help us identify the best way Twona can be tailored to your needs.

Me: Wow, those are great features indeed. How long would it take for Twona to be implemented for my team?

Technical Sales Consultant: We’re glad you find the features valuable! The implementation timeline for Twona can vary depending on your specific requirements, the complexity of your workflows, and how quickly your team can adapt to the new system. However, our goal is to make the implementation process as smooth and efficient as possible.

Typically, we can have Twona up and running in under a week. We assign a dedicated Customer Success Manager (CSM) to guide you through the onboarding process, assist with gathering relevant data, configure the platform, migrate existing data, and train your team on how to use Twona effectively.

The CSM will work closely with you to ensure the implementation timeline aligns with your needs and resources. They will also provide ongoing support to help you optimize the system and get the most out of Twona’s features.

Is there a specific timeframe you have in mind for implementation, or any concerns about the onboarding process that we can help address?

Me: I would like to present this to management first. Will you be able to share a quote with me?

Technical Sales Consultant: Absolutely! We’d be happy to provide you with a quote tailored to your specific needs. In order to give you the most accurate pricing, we’ll need some more information about your team size, the number of users who will be accessing the platform, and any specific features or customizations you might require.

Once we have this information, we can put together a detailed quote for you to present to management. If you’d like, we can also provide additional materials or join a call with your management team to help present Twona and address any questions or concerns they may have.

Please feel free to share the necessary information, and we’ll get started on preparing a quote for you right away.

Me (giving feedback on its performance): Make it more specific and try to close the call with a specific action point, for instance a specific date for a follow up call.

Technical Sales Consultant: I understand that you’d like to present this to management first. To help you with that, we can provide a tailored quote and any supporting materials you might need for your presentation.

In order to give you the most accurate pricing, please share the following information:

- Your team size

- The number of users who will be accessing the platform

- Any specific features or customizations you might require

Once we have this information, we can prepare a detailed quote and additional materials for you to present to your management team. To ensure we’re available to assist you further, let’s schedule a follow-up call after your presentation to management. How about we pencil in a call for next week on [specific date] at [specific time]? This will give us an opportunity to address any questions, concerns, or feedback that may arise from your management team.

If that date and time work for you, please confirm, and we’ll send you a calendar invite. Also, feel free to share the necessary information for the quote, and we’ll get started on preparing it for you right away.