Picture this scenario: endless email threads, multiple attachments in several emails as the size limit is reached, wrong attachments sent, lots of back-and-forth to explain that the attachment was wrong and here is the correct one, version confusion… If this is your day-to-day, you can see how it is a recipe for delays, miscommunication, and even the occasional oversight that can have far-reaching consequences.

Thankfully, you can stop that chain of inefficiency and elevate packaging approval processes to new heights of effectiveness—using digital solutions that go beyond the limitations of email attachments.

Rephrase

The Drawbacks of Using Email for Approvals

While email has earned its place for business communication, it proves inefficient when managing essential tasks such as approving packaging designs due to several shortcomings:

1. Disconnected Communication: Keeping track of context and accurately recording changes can be tough due to the scattered nature of email threads.

2. Confusion with version management: The presence of multiple attachments with nearly identical names could breed misunderstanding, chiefly when various editions are being scrutinized at the same time.

3. Sluggish replies: Overfilled inboxes or a surge of incoming emails may result in important messages being missed, leading to holdups in the approval process.

4. Ambiguous Responsibility: Figuring out who has examined or greenlit a design at any moment proves difficult, rendering accountability a fizzy concept.

The Digital Leap: What Modern Approvals Demand

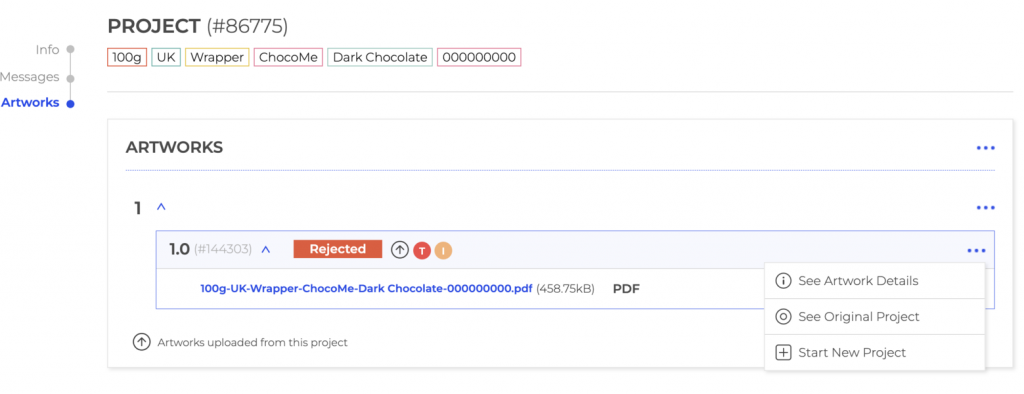

Fortunately, there are digital solutions that tackle the challenges of packaging approvals. These solutions offer a range of features that revolutionize the approval process:

1. Collaborative Workspace: Imagine a virtual space where stakeholders can congregate, review designs, provide feedback, and hold discussions—all within a single, organized platform.

2. Version Tracking: A digital system maintains a comprehensive history of design versions, enabling easy comparison and minimizing errors caused by outdated versions.

3. Transparent Approval Paths: Digital solutions allow you to define and visualize approval paths clearly, ensuring designs navigate through the correct channels without bottlenecks.

4. Automated Reminders: Say goodbye to chasing approvals. Automated notifications ensure that reviewers are prompted at the right time, reducing approval cycle times. You can also choose to send manual reminders.

5. Accountability and Audit Trails: Each action is recorded, creating an audit trail that clarifies who did what, when, and why—an essential feature for compliance-driven industries.

The Transformative Impact: Efficiency and Precision Redefined

Do you need to hear about the advantages of using such a digital solution ?

1. Streamlined Workflows: With collaborative workspaces, design reviews become intuitive and streamlined, eliminating the confusion associated with email chains.

2. Rapid Turnaround: Design approvals take less time, enhancing your ability to bring products to market swiftly and seize new opportunities.

3. Improved Accuracy: Version control hiccups and miscommunications become a thing of the past, reducing the chances of errors slipping through the cracks.

4. Compliance : Industries subject to regulations can breathe easier knowing that an accountable, traceable process is in place.

=====

So, are you ready to leave the era of email attachments behind and embark on a journey towards efficient, compliant, and precise packaging approvals?

If you are, please give a try to our approvals solution and then, contact us to help you implement it for your team.