As this year comes to an end, we want to take a moment to reflect on the months past and thank our clients for their continuous support and confidence in Twona.

The last months we have released a lot of new functionality improvements (you can check some of them here: https://www.twonas.com/updates/), many of them as a result of customer feedback. For us this is a fantastic result, to be able to collaborate with clients to make our tool even more robust and better fitting the industry needs. This also shows that our customers do not see the limitations but mostly the possibilities that the tool offers to their daily work, which makes us extremely happy.

Some of the work that was performed by the team was also not visible, but changes in infrastructure have made Twona even more robust and faster to the end user.

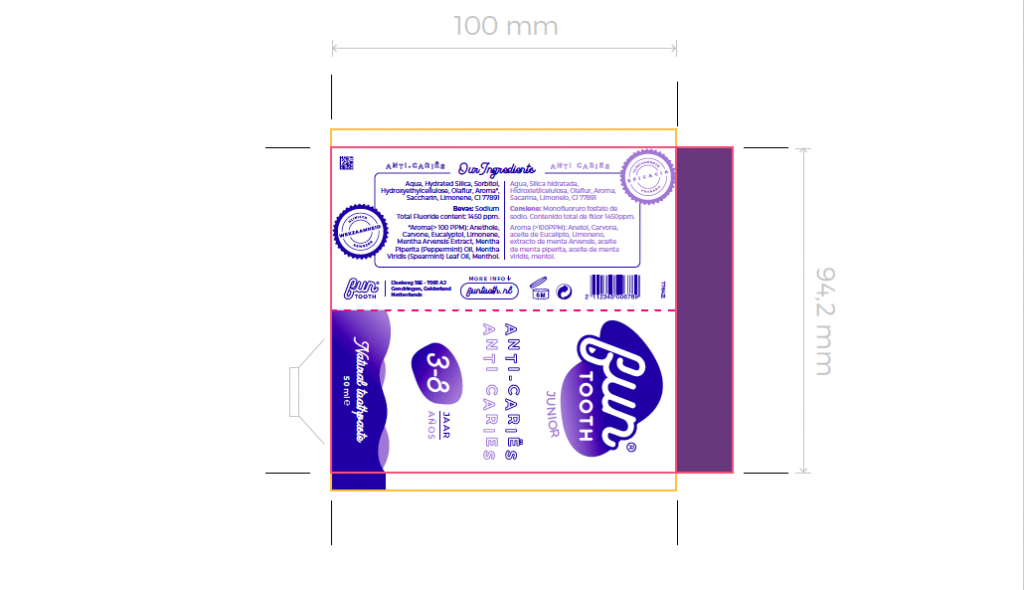

We also completed several new implementations, a few of which are considered some of the most complex we have worked on so far – and in record time, too! Those included not only configuration of several work processes, as well as complex permissions and automations, but also data migration and validation services. If you did not know we offer a validation service, download our white paper : Fast track validation, or contact us.

Our sales team was present at several events and exhibitions, where they were able to meet new prospective customers (some of which are now clients ❤️ ) as well as existing users of the platform. We are currently finalizing the list of events we will be attending in 2025. If you are attending any events next year, share those with us, we would love to meet you there face to face!

All the team has been working on multiple tasks, diversifying in some cases from their regular daily jobs, and with a lot of involvement in daily operations, to understand better what the clients need and what situations they encounter, so we can serve current and future customers better.

We are extremely proud of our client reviews, not only on our testimonials, but also on their NPS scores which keep improving over time (NPS of 68 for 2024); we do take feedback seriously, so we can make an even better Twona for our users.

We are looking forward to 2025, and to continue building a better Twona and growing our customer and partner base. We hope you will be around to see it all happening!